Innovative Solutions for Food Processing and Packaging Industries

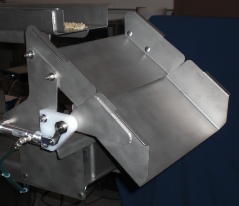

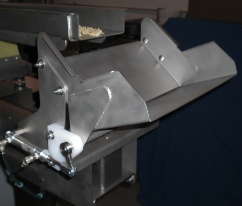

CRESCENT MAGNA CHECK (Patent Pending)

The new Magna Check is an in line weight checking device to report production rate of a process line, by weight. It may be employed independently by inserting it between two conveyors to report the rate of product flow. It may also be employed in conjunction with a weigh belt or Magna Weigh to report and correct throughput. In this case it may be used as a second check, eliminating the need for manual catch test to ensure the weighing device is functioning properly. It computes feed rate by sampling weight for a given amount of time and interval, providing feed rate information and sending correction signal if desired. This unit may be custom designed to suit particular application requirements.

The purpose of this device is to check the flow rate, in terms of weight per unit time, of free flowing products. This may apply to feeders which feed products volumetrically or check the flow rate of products being dispensed gravimetrically. In the case of volumetric feed systems it is desirable to check the feed rate by weight as different products may have different flow rates since the bulk densities of products differ. So for the same volumetric feed rate various products would have a different feed rate, by weight. In the case of feeders which feed products by weight (examples being weigh belts or Magna Weigh US Patent 5,780,780), this device may provide an independent check to ensure the feeders are feeding the same as the set point. If the feeders are not feeding at the set point, then this device may issue a signal so that the feeder may automatically correct the feed rate to comply with the set point.

| Interesting Projects |

| Our Personnel |

| Manufacturing Capabilities |

| Electrical Capabilities |

| System Set-Up |

| Drawings |

| Brochures |

| Videos |

| Research and Development |